Containment Details

Foam-Wall Driver Over

Our Foam-Wall Drive Over containments are the best solution to contain leaks or accidental spills in the oilfield. Designed for use under Fracking Equipment and tractor/trailers, our Foam-Wall Drive Over containments are constructed of the toughest material available on the market today, with a specialized coating applied to provide added durability with a proven non-slip surface. These containments have a perfected weight/surface area ratio which results in enough weight to stay in place in windy conditions, but yet not so heavy that health issues arise with the moving/adjusting of containment by hand. From sizes of 4' x 4' to 40' x 80', our large inventory is sure to have you covered.

- Common uses are endless including frac equipment, diesel tank storage and disconnecting hoses

- Walls made of durable 4", 5" or 6" foam

- Drive in and out without worries

- Very adaptable Non-slip surface

Quick-Latch

Quick-Latch containments are constructed as a 1-piece, quick set up unit to fill your containment needs under various oilfield equipment. Commonly used for tank farms on the drilling rigs, frac tanks, and fuel tanks, the Quick-Latch containment is setup by professional CCS staff in a matter of minutes. It’s 1-piece construction enables it to be setup or tore down quicker than any other containment in the industry. It is extremely durable and has proven itself time and time again. The Quick-Latch is offered in virtually every size large or small and is available with a wall height of either 13", 18" or 24". Heavy duty Track Mats are provided for added protection and traction.

- Commonly used for tank farms, fuel tanks, and frac equipment

- 13", 18" or 24" walls

- Extremely quick set-up and tear-down time

- Liner always reused and easily repaired as needed

- Internal wall bracing system for a smaller footprint and reduced tripping hazards

- Structurally engineered to resist extremely high wind

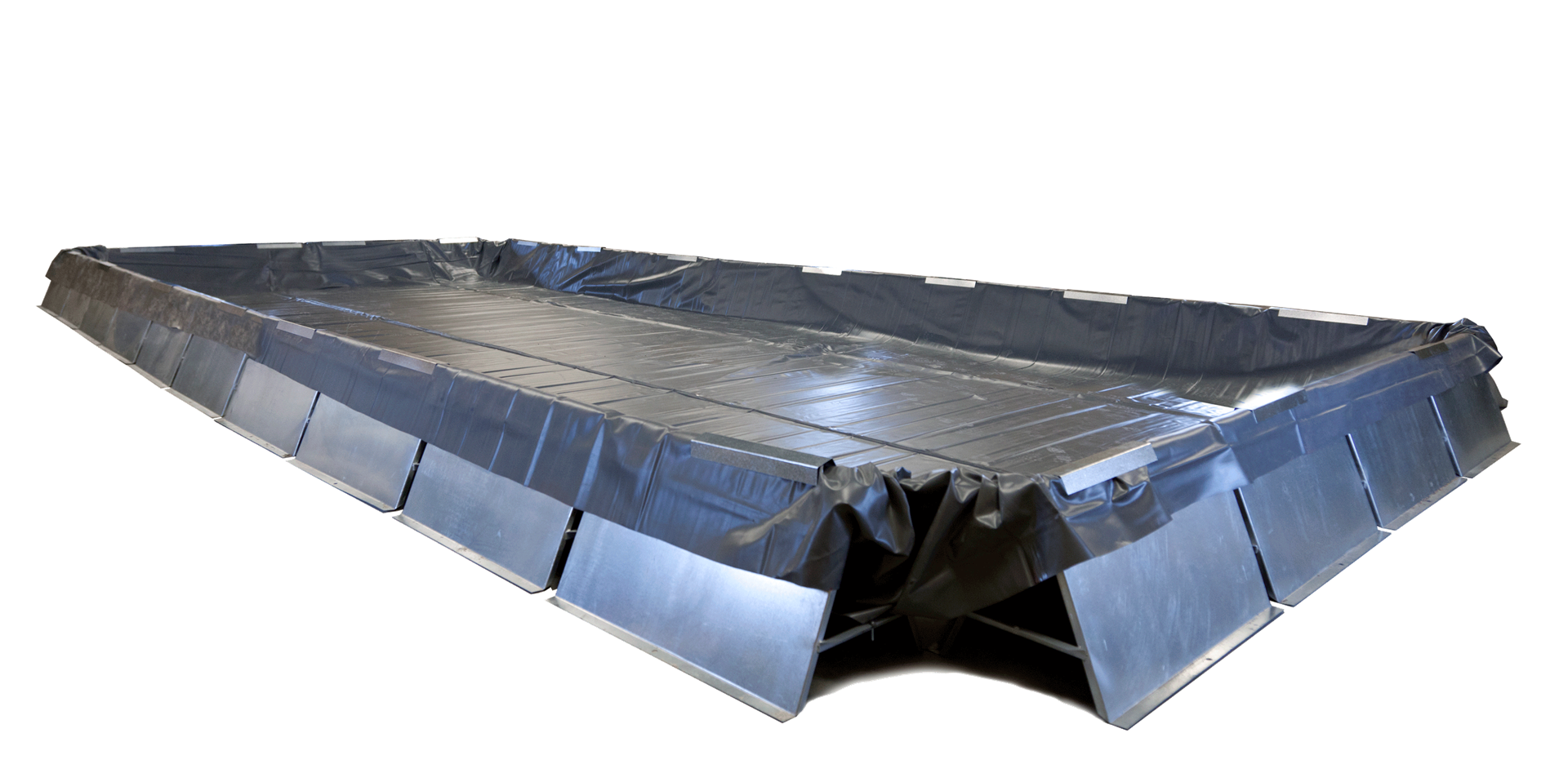

Easy A

The Easy A containment consists of multiple "A" shaped pieces of galvanized steel. The sections are 2' tall x 4' wide, and are arranged to the desired size. A durable disposable liner is then placed inside and clamped down to the top of the "A" frame walls and corners which are firmly bolted together. This containment system provides reliable containment that is the most economical for any containment need. Commonly used for tank farms and fuel tanks on the drilling rigs.

- Commonly used for tank farms and fuel tanks

- 2' walls

- Constructed with connecting galvanized "A" frame panels

- Resistant to high wind without anchoring or added weights

- Liner replaced as needed (usually every well)

Internal L

The Internal L containment system is CCS’ go-to product when you need secondary containment under large volumes with as small a footprint as possible. The Internal L is manufactured with our standard industry leading poly material. Designed with 3’ high walls, a heavy-duty galvanized top rail is threaded through the hem along the entire perimeter, corner pieces are inserted, and the containment walls are risen with our patented L braces that slide into place and support the integrity of the structure. The internal wall bracing system reduces nearly all trip hazards. The 3’ wall provides reassured EPA compliance for any job. Set-up and tear-down time is extremely quick. Track mats are provided for added protection and traction.

- Commonly used for tank farms and fuel tanks

- 3' walls

- Quick set-up and tear-down time

- Liner always reused and easily repaired as needed

- Internal wall bracing system for a smaller footprint and reduced tripping hazards

- Structurally engineered to resist extremely high wind

Accessories

- Ground mats for underneath berm

- Track mats for driving on top of berm

- Tank Setting Pads for setting uprights inside berm

- Safety crossover ladder

- Hose bridges for running hoses in/out over berm walls